Injection Mold Supplier, Plastic Production, One Stop Quotation

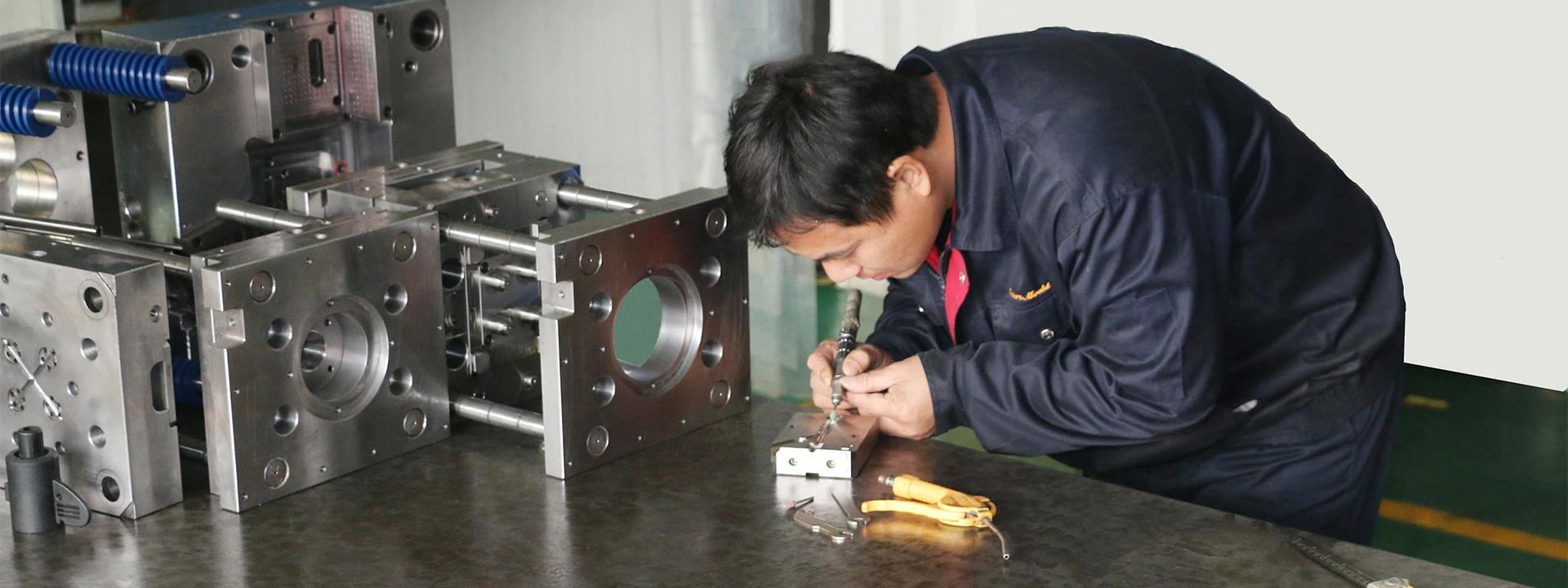

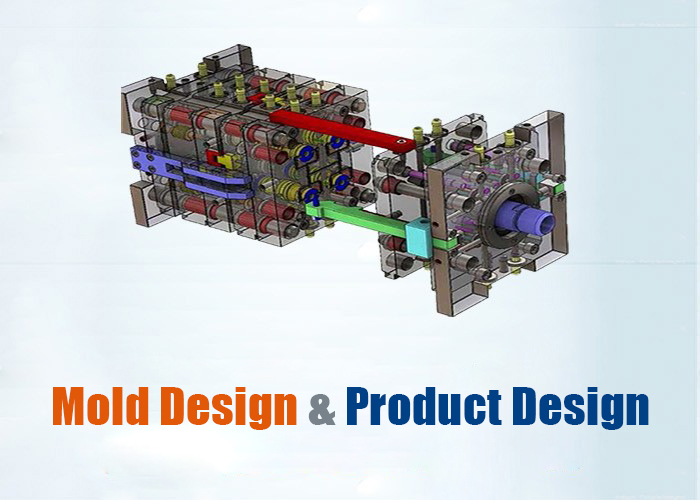

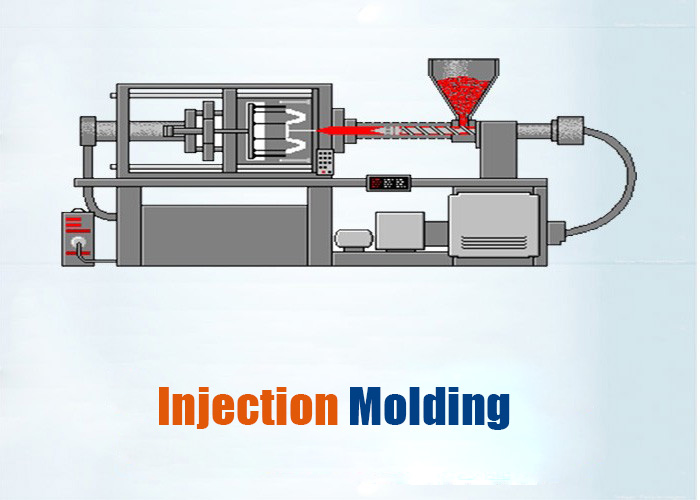

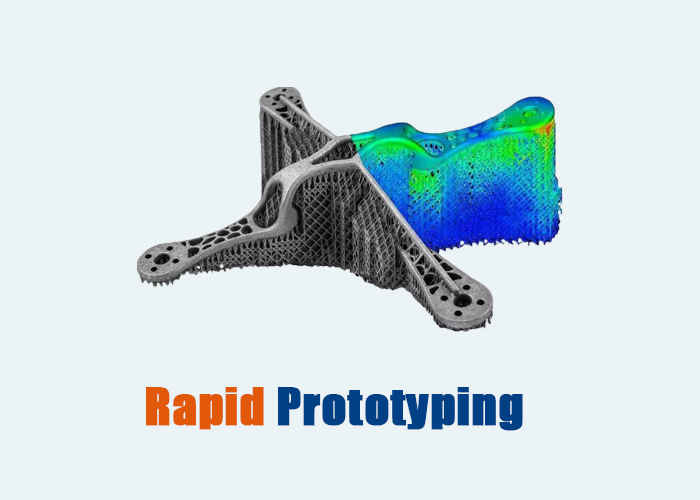

FutureMould aims to provide a best future to customers through the joint service including mold&product designing, OEM Plastic Injection Mould manufacturing and mass production of plastic product. Many of our molds and plastic products, such as car sensor plastic mold, medical product injection mold, plastic airbag cover, oil engine fuel cap, and etc, have already been admitted by many famous international companies.

-

Recently, our company participated in the 24th DMC International Mould Technology & Equipment Exhibition, held at the Shanghai New International Expo Centre from June 4th to 7th, 2025.

10-06-2025 -

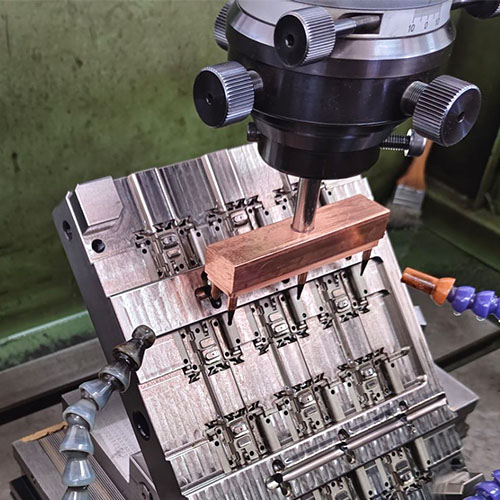

In injection mold processing, machining is one of the core stages in the entire mold manufacturing process, playing a foundational role in determining the mold's structure, precision, and functionality.

30-05-2025 -

The advantages of Electrical Discharge Machining (EDM) in plastic mold manufacturing are mainly reflected in its "ability to machine complex shapes," "suitability for high-hardness materials," "high precision and excellent surface quality," and "good machining stability."

30-05-2025 -

The choice of raw materials for plastic gears is critical, directly impacting their service life, noise levels, transmission efficiency, and cost.

29-05-2025